|

|

The R-Spec rotor is a high quality cast iron race rotor and we added more mass, and vane structure for maximum thermal capacity. In development for almost 2 years with the end goal to have a purpose built, race rotor that offered a substantial improvement in rotor life. R-spec now features T-bobbin floating hardware to limit the “bell” effect of the rotor hat, while also eliminating the common noise issues associated with floating rotors. The rotors come in a slot only finish and are available as an upgrade to any of our 14” Extreme+ systems and feature a unique hat (this is a floating rotor). |

|

||||

|

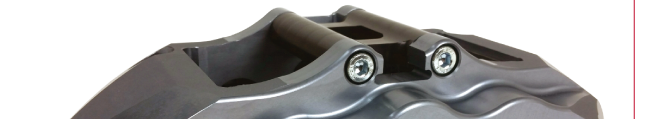

The XTR is Baer’s flagship offering, featuring a forged mono-block caliper that is mounted to a 14” or 15” 2-piece rotor. It employs current state of the art race technology usually only found in very expensive race calipers, and Baer brings the same technology to the road going/ street market. Available as individual calipers, or as an upgrade to any Extreme+ brake system MONO-BLOCK DESIGN Machined out of one solid piece of 2618 aluminum for the ultimate in rigidity and weight reduction. |

|

|

|

||

|

||||||

|